Buflovak Atmospheric Cooling Drum Flaker

Manufactured by Hebeler Process Solutions, USA

Cooling Drum Flakers are the most compact and efficient method to cool an incoming molten product to a solid flaked product utilizing thin film continuous cooling via conductive heat transfer.

Cooling Drum Flakers are utilized in food, chemical, environmental, and pharmaceutical applications for products such as acetic acid, calcium chloride, caustic soda, edible oils, fatty acids, polyethylene glycol, steric acid, waxes and zinc stearate.

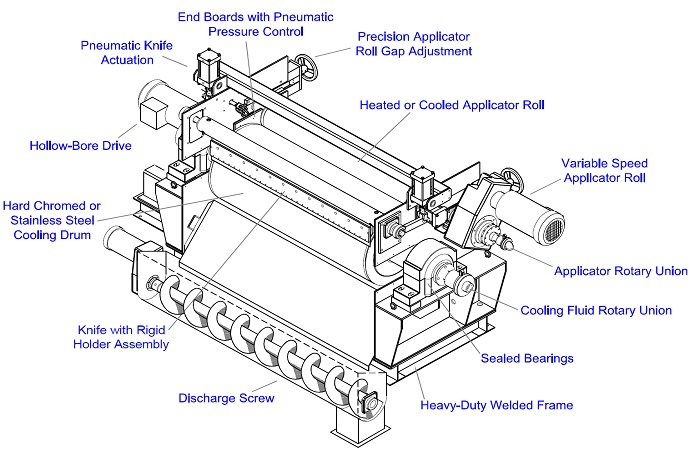

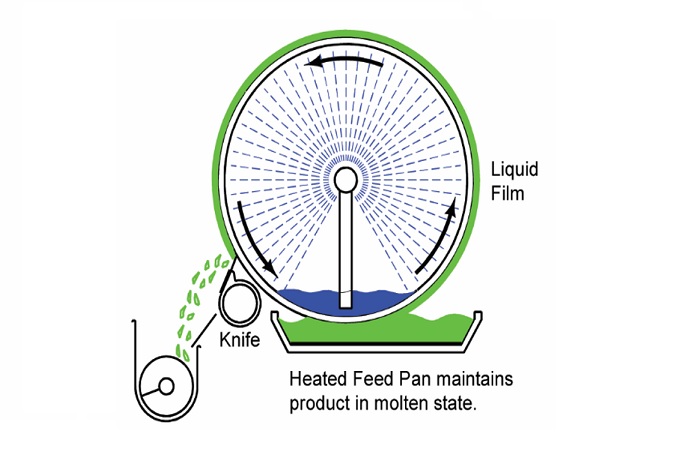

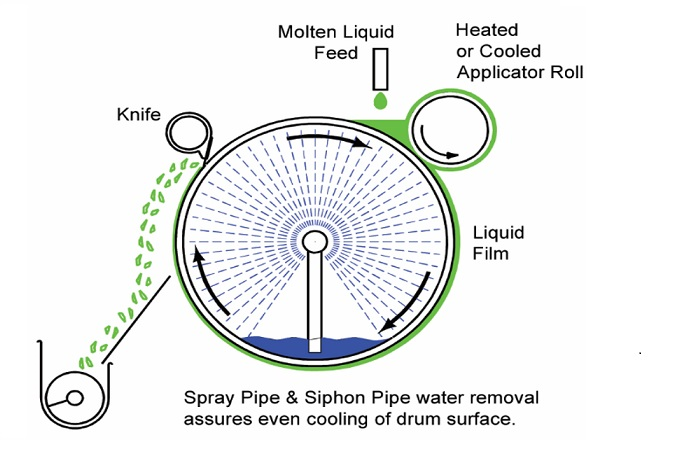

It consists of a rotating drum with a cooling liquid sprayed on the inside and a product specific application method for applying the molten product to the drum surface. Standard applications methods are; a dip feed pan usually used for low viscosity products, applicator roll usually used for heat sensitive products or agitator roll usually used for super-cooling products. The solidified product is 100% removed from the drum surface by ridged knife-bar assembly.

Due to environmental and health safety requirements, cooling drum flakers are usually enclosed in a number of specially designed enclosures specifically suited for dust containment or toxic vapor containment and/or provide an inert gas operating environment for oxygen-sensitive products