Coarse Grinding

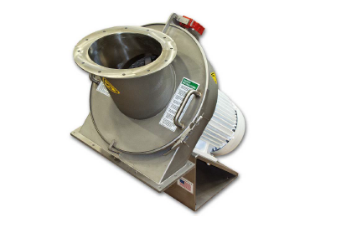

RA/RP Disintegrator

Manufactured by Bepex International LLC, USA

RA and RP Series Disintegrators are widely used for fine pulping of many food products, and for fine dispersing and homogenizing in both the food and chemical industries. In addition, they have the capability of doing high speed shredding and wet grinding of many fibrous and other extremely tough materials.

The angled design of the grinding chamber allows for the use of a screen that completely surrounds the rotor, thus offering double the screen area than similarly sized horizontal shaft units. Feed materials are delivered to a special designed inlet as liquids, solids or pastes, using conventional conveyors or pumps. Once the material enters the inlet chute, it drops to the hammer stack. Typically, the lower limit on particle size is 250 microns or 60 mesh. Numerous screen types offer maximum flexibility. The various options ensure production of the required final product.

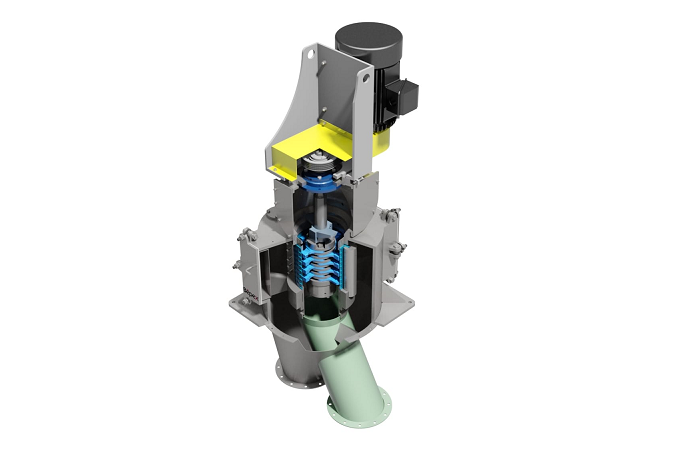

RD Disintegrator

Manufactured by Bepex International LLC, USA

The Bepex vertical Disintegrator is a versatile, heavy-duty hammer mill utilized in the food, chemical, and polymer markets. The Vertical Disintegrator has a bolted, 360 degree screen which surrounds a series of either fixed or swing hammers that are pinned to a series of rotor flanges. The body of the machine incorporates an integral bearing support to facilitate the use of either screw feed conveyors or delumping feeders.

When separation of a hard-to-grind portion is desired, a dual discharge is utilized. This allows for the removal of foreign objects such as rubber bands, cellophanes, and wire, or process specific items like garlic or ginger root skins.

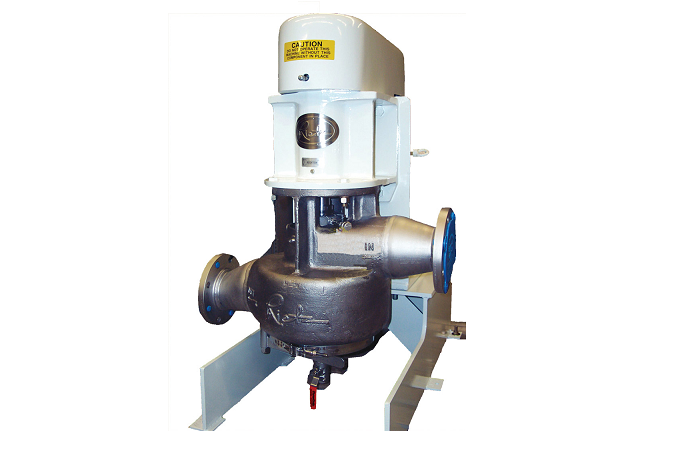

RI Disintegrator

Manufactured by Bepex International LLC, USA

RI Series Disintegrators are specifically designed for in-line installation, where they function without impeding the process flow. Their primary applications are mixing, delumping and dissolving of fluids, slurries and pastes, and the grinding and separation of high fiber solids.

Once material passes the inlet flange, it flows directly into the hammer stack, where high speed hammers impact the material resulting in a combination of size reduction methods: Impact with hammers, edges of screen perforations, attrition between hammer and screen and impact from other material. Material is held in the grinding chamber until it is small enough to exit through holes in the screen. The screen size and tip speed affect particle size and distribution.