Block Grinding

Rubber Chopper

Manufactured by Bepex International LLC, USA

The Bepex Rubber Chopper's extra heavy-duty design can shred blocks of rubber and plastic in seconds at high torque rather than high speeds. It consists of a series of adjustable anvils and rotating hammers, an orifice plate, and optional rotating cut-off knives.

As the block is dropped into the hopper inlet, the sharp edges of rotating hammers bite into the block and shear it into chunks against the anvils. The chunks are pushed through the barrel and repeatedly chopped into smaller pieces, until they pass through the orifice plate. The optional cut-off knives shear the product as it exits the plate to produce even smaller particles. Various drive assemblies and chopper sizes are available to meet a variety of production requirements.

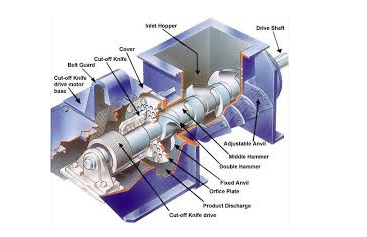

Extructor

Manufactured by Bepex International LLC, USA

The Bepex Extructor is a heavy duty, food grade machine designed to reduce the size of large blocks (no precutting required) of materials. Low speed operation and specially designed cutting elements minimize temperature rise. Efficient operation results in high capacity at relatively low power input.

Blocks or large pieces enter the feed hopper on a continuous basis. Forward conveying rotating hammers cut into the material and shear it into smaller pieces against the fixed anvils while moving the material toward the discharge. At the discharge, material is cut between the end hammers and the orifice plate for final particle size control.