Mixing and Blending

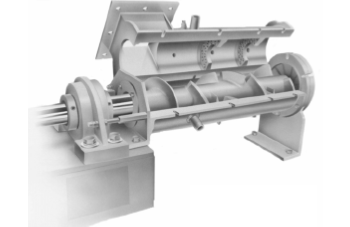

Hydramix

Manufactured by Bepex International LLC, USA

The Hydramix consists of twin intermeshing paddle rotors operating at different speeds in a covered trough. In hydration applications, liquid is injected through nozzles located near the feed inlet to promote thorough mixing. Injection nozzles can also be located along the length of the unit to provide liquid addition during stages in mixing. The unit is jacketed and the rotors can be heated to promote reactions or to prevent sticking.

Mixing speed and paddle angle can be adjusted separately to vary the amount of mixing energy imparted to the material independent of conveyance requirements. Ultra-low rotor speeds result in low-shear operation to provide excellent mixing while preventing particle damage even during long residence times.

Ribbon Blender

Manufactured by Bepex International LLC, USA

The Ribbon Blender is continuous mixer having a U-shaped vessel. It is useful in applications where back mixing is required. It operates at a slow speed; minimizing particle breakage and short circuiting. It can also be used as a continuous indirect heat exchanger by using a jacketed vessel. It has residence time from minutes to hours.

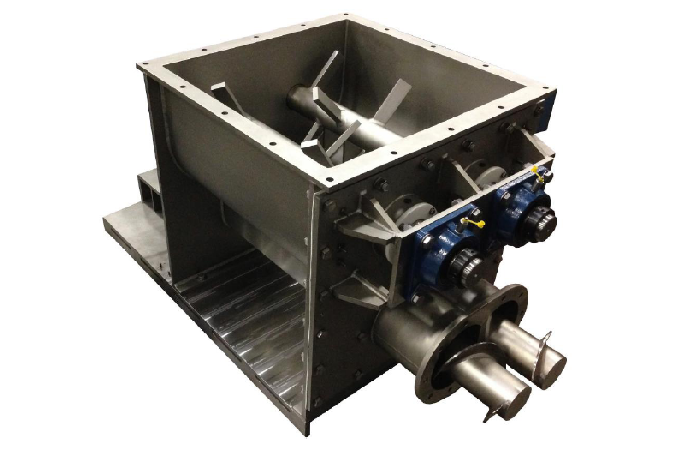

Wet Cake Feeder

Manufactured by Bepex International LLC, USA

Mixing or drying applications require accurate feed delivery which can be difficult with wet or sticky materials. The Wet Cake Feeder is designed to easily interface with your downstream equipment. Delivery of material without the introduction of excess shear is possible and rates are simple to control with our Wet Cake Feeder.

The operation homogenizes the feed material, converting slug flow to continuous flow. In addition to providing uniform feed, dead spots and lack of flow are eliminated by the unique agitator construction. Twin cantilevered intermeshing screws penetrate the vessel body, preventing buildup at the interface of the feeder and downstream equipment.

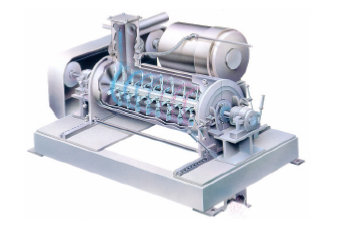

Turbulizer

Manufactured by Bepex International LLC, USA

The Bepex Turbulizer is a high shear speed paddle mixer offering high capacity in a compact space.

This continuous mixer offers:

- Adjustable paddle elements for control of housing clearance

- High paddle tip speeds

- Flexible control of residence time and mix intensity

- Application-specific control of shear on materials

The thin working layer of material in this paddle mixer promotes efficient indirect heat transfer in jacketed models. A list of successful Turbulizer processes includes dry powder mixing, hydrating hard to wet powders, slurry mixing, coating, sterilization, crystallization, granulating, homogenizing, delumping, finishing, and coating.

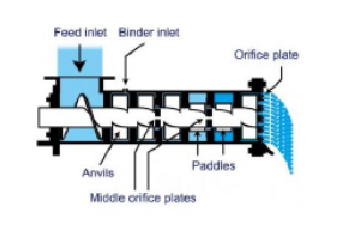

Extrud-o-mix

Manufactured by Bepex International LLC, USA

Extrud-o-mix is an efficient low pressure mixing and forming extruder can generate uniform, free-flowing, dust free pellets or particles. The Extrud-o-mix is primarily designed for combining dry powders with liquid streams to produce a paste or dough suitable for extrusion. However, with efficient continuous mixing, adjustable shear input, and heat transfer available in the housing and the rotor the application list becomes very diverse.

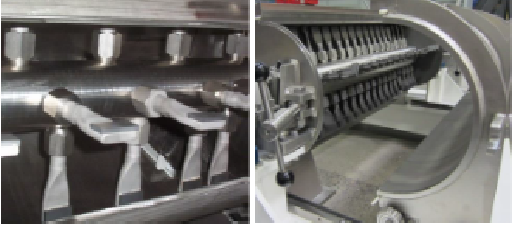

Extrud-o-mix consists of a single horizontal shaft carrying rows of hammers arranged in a spiral pattern. Stationary anvils attached to the housing are inserted between the rotating hammers. In the mixing process as the hammer passes the anvil a portion of the material is moved forward and the remainder lags behind. This conveying effect provides a continuous kneading, mulling, and mixing action on materials ranging from light pastes to heavy dough or putties.